Aspire Food Group Manufacturing Facility

Aspire Food Group

~$90 Million

architects Tillmann Ruth Robinson

EllisDon

2019

The Aspire Food Manufacturing Facility in London, Ontario, is a groundbreaking project that positions Canada as a global leader in sustainable food production.

Operated by Aspire Food Group, the 170,000 square foot facility is the world’s largest fully automated cricket protein manufacturing plant. Designed to address the growing demand for alternative proteins, the facility integrates cutting-edge robotics, climate control, and AI-driven monitoring systems to optimize insect rearing at scale. The crickets produced are processed into high protein powder used in pet food, human nutrition, and agricultural products.

The facility exemplifies innovation in vertical farming and waste-to-value practices, consuming fewer resources than traditional livestock operations. Located in the Advanced Manufacturing Park, the project reflects strong collaboration between public and private sectors, including federal and provincial funding. Aspire’s facility not only supports the emerging agri-tech industry in Southwestern Ontario but also contributes to a more resilient and sustainable global food system.

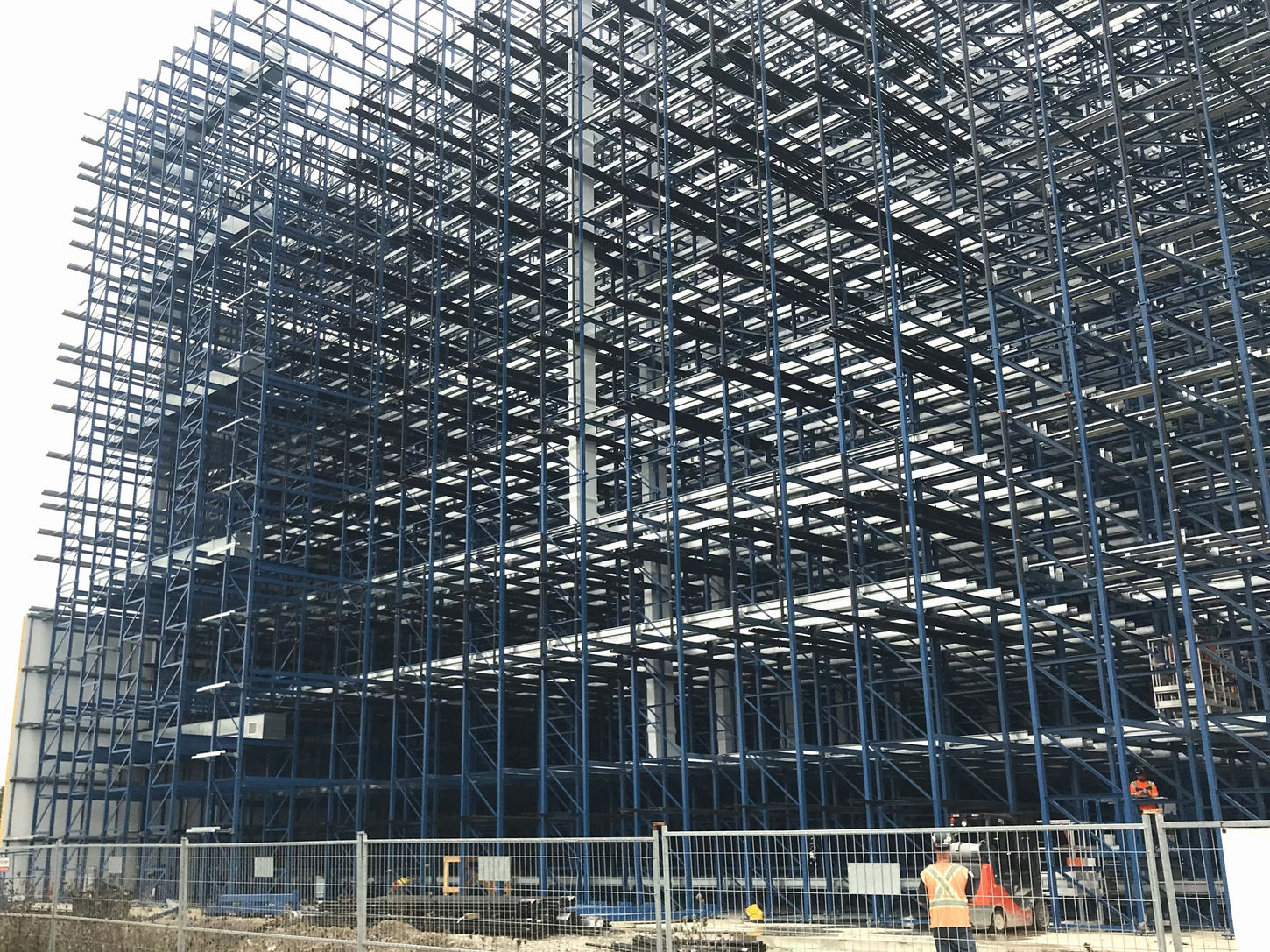

The Aspire Food Facility combines industrial durability with precision engineering across its 165,000 ft² footprint. An insulated Kingspan metal panel envelope minimizes thermal bridging to maintain strict temperature control for insect rearing and frozen storage. A 97-foot-high Automated Storage and Retrieval System (AS/RS) forms the core layout, supported by heavy-duty steel racking integrated with roof and wall structures. A 600 mm thick raft slab transfers concentrated loads to the ground. Conventional steel framing supports office and processing areas, including heavy rooftop mechanical equipment. Uniquely, the design also addressed biosecurity by ensuring containment of crickets within the AS/RS zone.